component lifecycle strategy

optimise the life achieved of your components

Optimising the lifecycle of your fleet and its individual components is critical to the operating efficiency or your business, contributing to lower overall operating costs and increasing the operating margins of your fleet.

Equipment manufacturer recommendations for component life cycles are focused on their operating margins not yours. In some cases, component life can be doubled with the right lifecycle and condition monitoring strategy put in place.

Our approach to lifecycle optimisation focuses on applying a framework of extending life whilst minimizing the risk of failure.

how we can assit you

Current state review and analysis

Our approach to lifecycle strategy begins with you, the customer. We first seek to understand what you need to achieve from your assets and the life cycle that would support it. This is a critical first step as some customers may opt for a life cycle strategy that relies on upgrading an asset after short duration intervals, whereas some customers may opt to operate an asset to full life.

Once this has been established, we analyse the following areas:

- PM Service tactics – Condition monitoring, lubrication tactics, filtering and kidney looping, non-destructive testing (NDT)

- Asset life cycle requirements – What life span do you require your asset to be operational for

- Component life cycle requirements – Various options exist including regular interval or calendar based, operating hour based, condition based, and run to fail change out models.

- Appetite for risk – We review your fleet redundancy and appetite for risk

Reccomenndations for an optimised life cycle strategy

After completing a thorough and in-depth analysis of your current state we create strategy recommendations aimed at improving the key areas of your fleet that will contribute to the greatest overall benefit. We can focus on any or all of the below areas:

- Preventative maintenance tactic alignment – We align filter and lubricant requirements and change out intervals. This results in a reduction in downtime and opearting cost by allowing for the consolidation of lubricants and filters, permitting bulk orders and buyer discounts. We can also assist with aftermarket filter and lubricant recommendations. This is particularly helpful with the large cost increases we are witnessing in todays market.

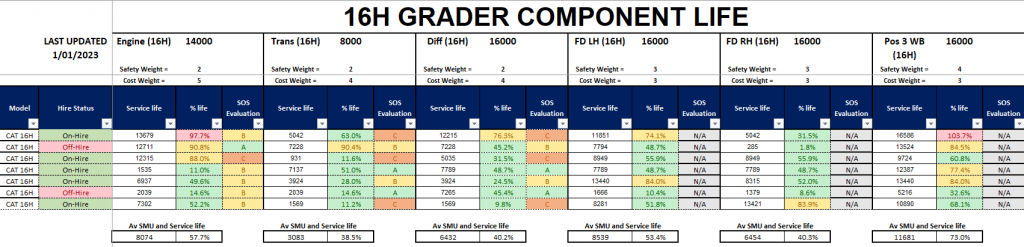

- Asset lifecycle strategies – We can provide strategies and frameworks designed to achieve the greatest life possible for your assets whilst minimizing risk. We do this through component health analysis and review systems. These systems are simple and effective, allowing for ease of use by anyone in your business.

- Component change out recommendations – We can provide continuous review and analysis services for the condition monitoring of your fleets components, make recommendations on change out intervals, and assist with upskilling your teams in recognizing when a component has achieved life. We also provide recommendations on change out tactics and strategies taking into account your appetite for risk.

let us optimise the life of your components

We can provide you an obligation free assessment of your current condition monitoring practices and provide some tips on how you can instantly make improvements that will positively effect your bottom line.